Advanced Servo Motors ...

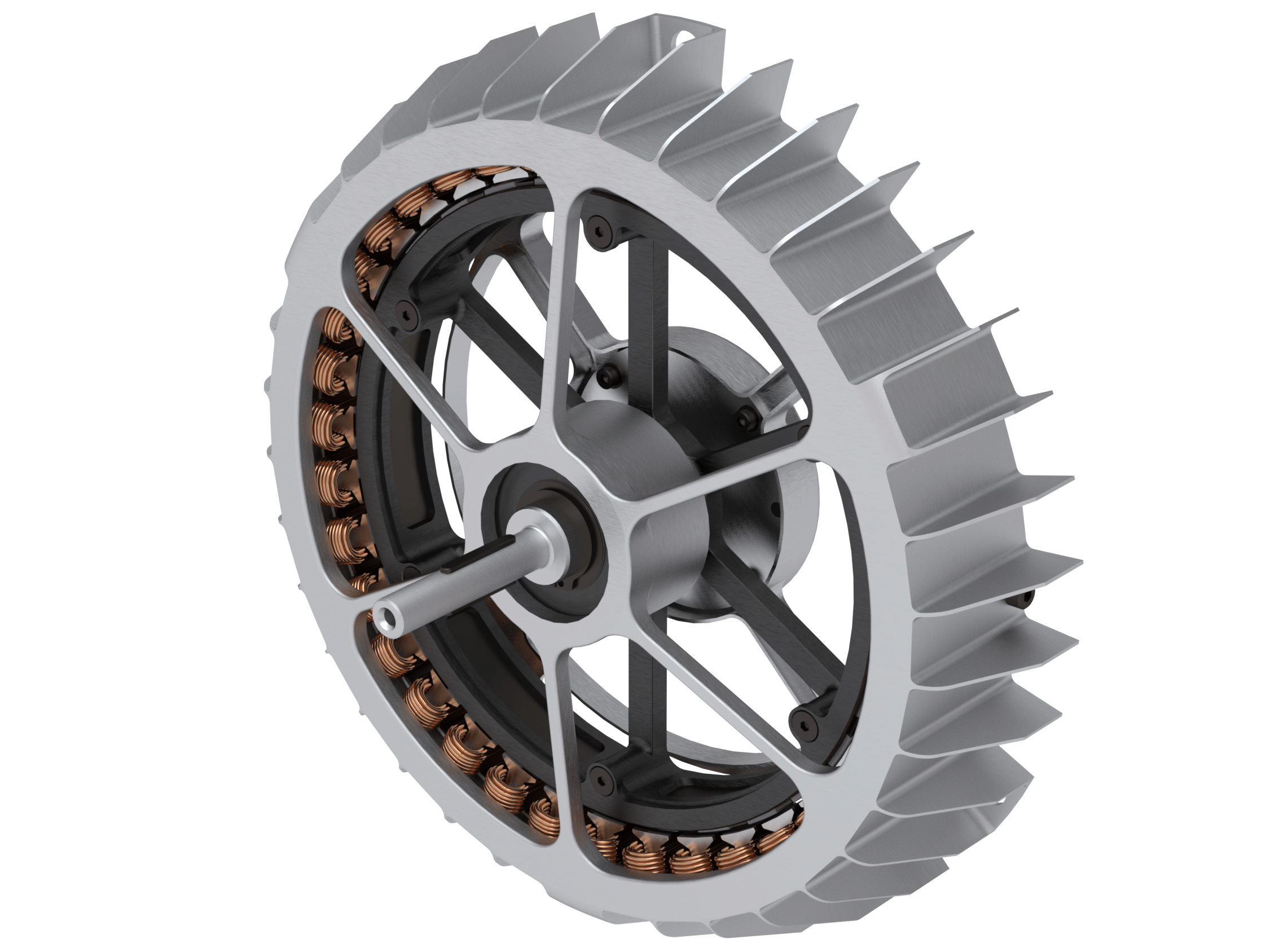

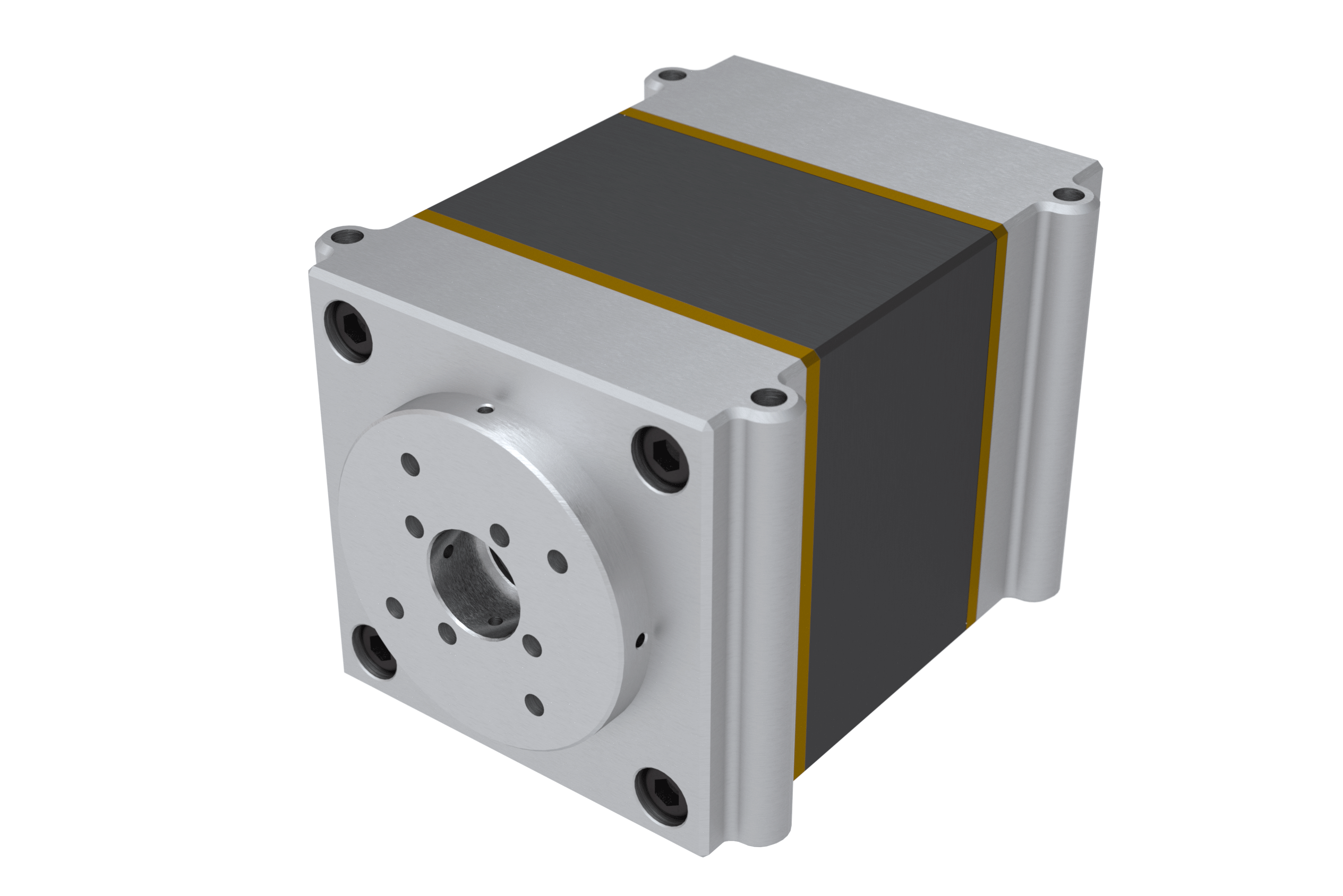

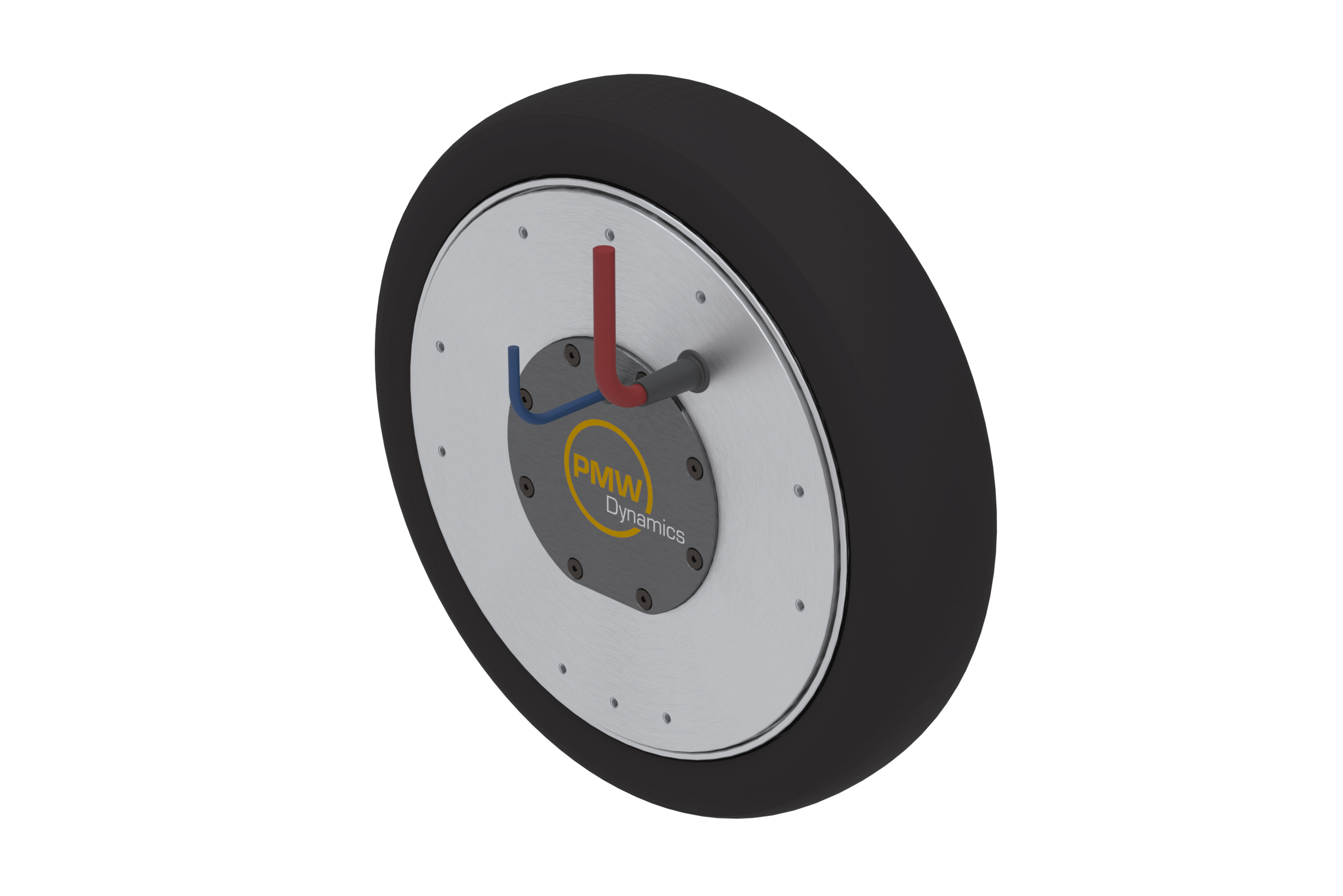

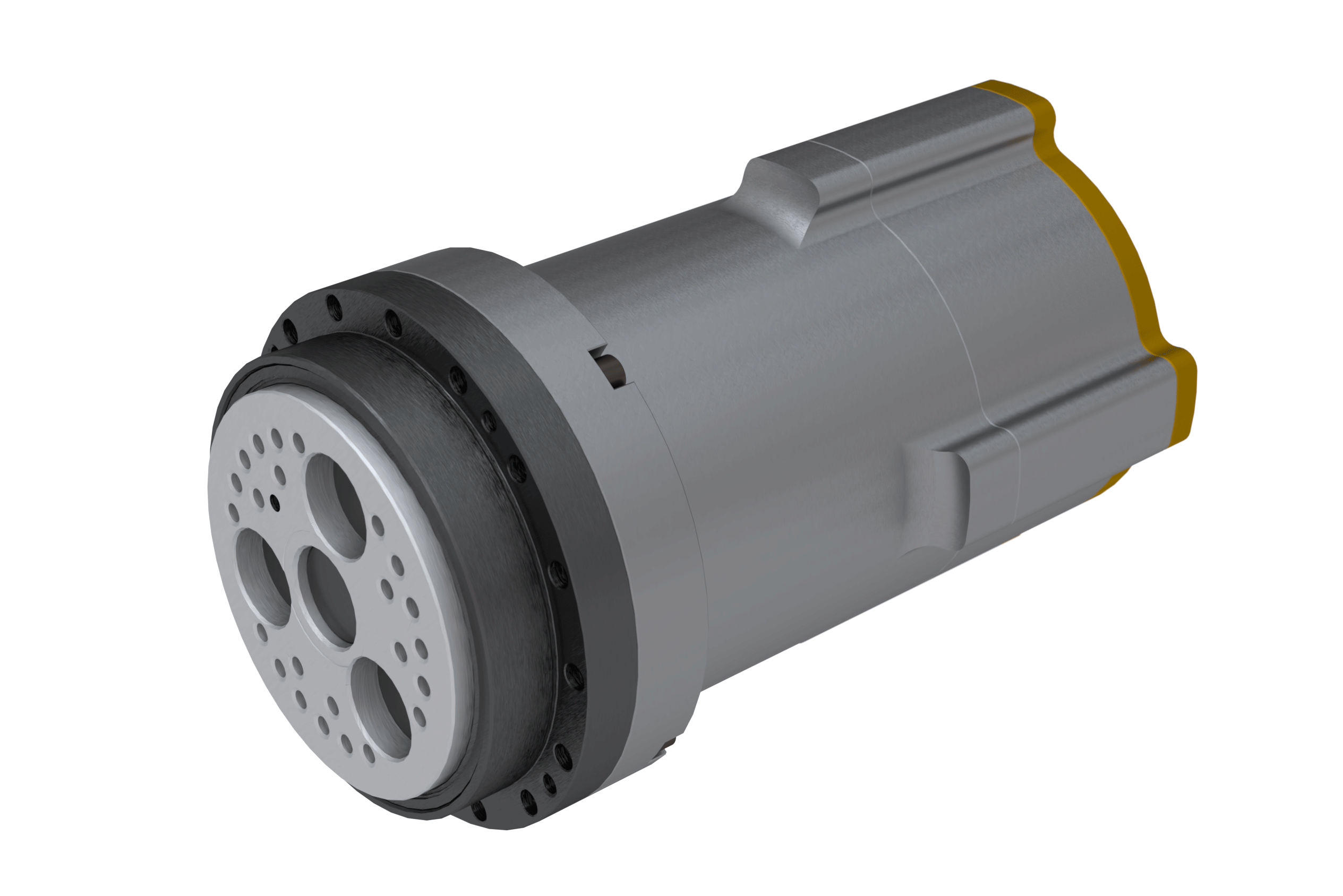

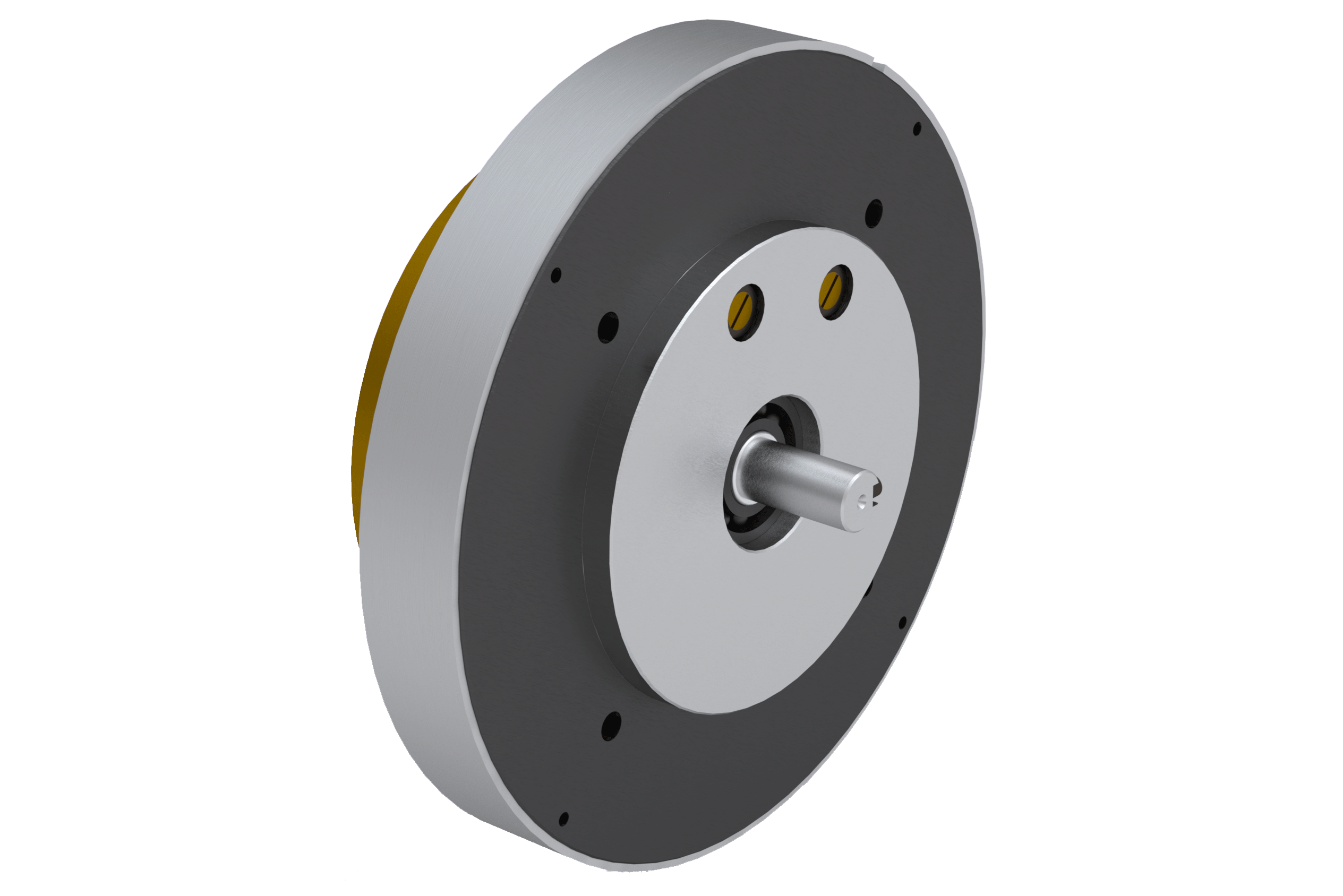

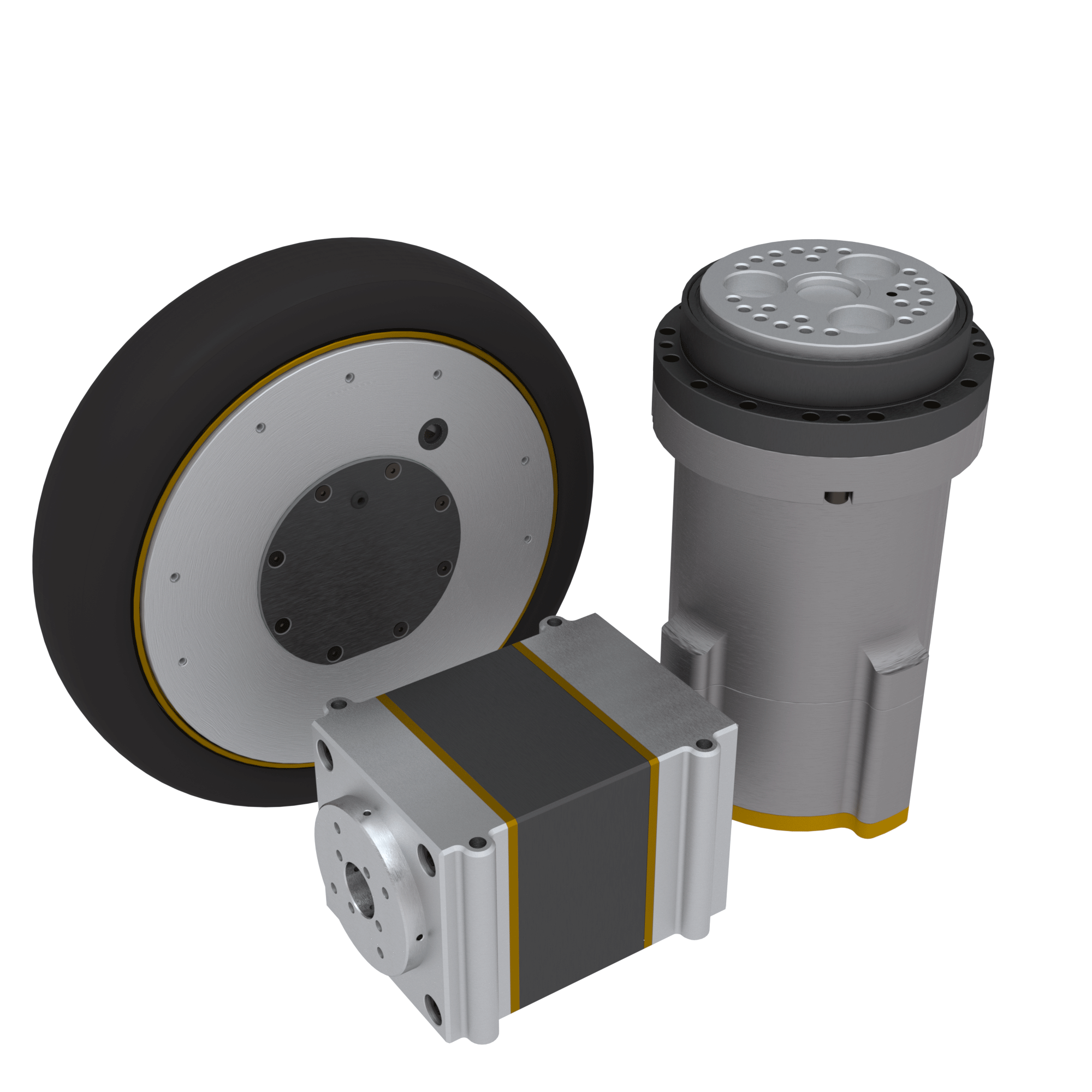

PMW Dynamics provide a comprehensive portfolio of advanced PM servo motors deploying both brush and brushless technology each bringing their specific benefits to an application

Remember your choice is not limited to catalogue items as PMW Dynamics have the capability to design and manufacture custom motors optimised to the exact requirement of your application

Industries Served by PMW Dynamics

A diverse range of industries rely on PMW Dynamics to engineer motor solutions design specifically for their demanding needs. Here's some examples ...

Bespoke Servo Motors

Why do you need a bespoke motor?

Often a standard off-the-shelf catalogue motor will suffice and, when it does, this is the seemingly the most obvious choice

However, there are many times when that catalogue choice unacceptably compromises some aspect of your application. This is when a bespoke motor has many advantages and is the correct solution

A bespoke motor will provide an exact match for your application ....

Four reasons why a custom motor is the better choice for your application ...

- Optimised Motor Performance - Speed, torque, power and efficiency exactly where it's needed rather than just being close

- Motor Form Factor - Shape, length, width, mass where needed for your application - no compromise

- Operating & Power Requirements - Operating voltage, current consumption specific to the application

- Designed Specifically for Operating Environment

Below is the typical route to engineer a bespoke motor for your application ...

- Definition Capture

- Concept Design

- Commercial Terms & Contract Award

- Electro-Magnetic Study

- Thermal Analysis

- Electro-Mechanical Design

- Manufacture of Engineering Samples/Prototype

- Design Validation

- Application Field Trials

- Full Production

And here's some examples ...

Motor Development Process

Understand how bespoke motor development is undertaken. Over numerous successful development programmes over many years, PMW Dynamics has enhanced and refined the process to ensure the delivered product always fully meets the original customer specification, in-budget and on-time. Find out more

Read moreReady to start a project?

Get in touch